What to choose - vibration casting or vibration pressing?

In the modern construction industry, two main technologies are used for the production of paving slabs, fences and other products: vibration casting and vibration pressing.

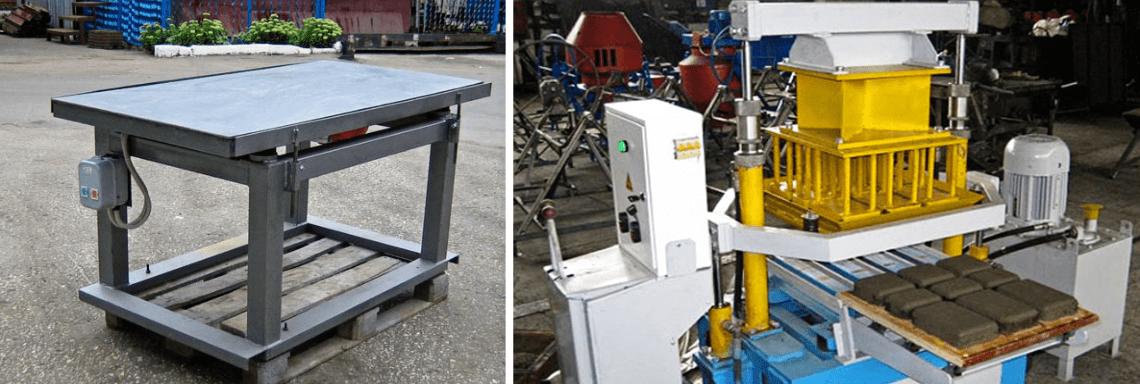

Vibratory casting technology

Vibration casting technology is widely used due to its advantages in the quality and aesthetics of the products produced. This technology involves casting concrete with compaction on a vibrating table. The result is products with the following characteristics:

- Dense concrete structure, superior in quality to ordinary concrete;

- Bright, rich colors that allow you to create a wide range of design options;

- Possibility of simulating various natural stones: marble, granite, malachite, etc.;

- Smooth or textured surface to suit different aesthetic requirements;

- A wide variety of shapes and sizes of products, providing a creative approach to design.

Using vibratory casting technology, it is possible to create mini-factories that allow the production of artificial marble, granite and other types of “stone”, paving stones, paving slabs, as well as large architectural elements such as wall panels, sidings, fence elements, small architectural forms .

Vibrocompression technology

In the production of building products using vibrocompression technology, three main components are used: binder, filler and water. Cement can be used as a binder and sand or any similar local materials as an aggregate. The result is products with the following characteristics:

- Low physical and mechanical characteristics (strength, wear resistance);

- Limited color range (solid shades);

- No imitation of stone surface;

- High porosity, which reduces resistance to moisture and frost;

- Limited range of shapes (5 or less types).

| COMPARE QUALITY |