Business plan for the “Minimum” program

The Camelot company offers a minimum program for entrepreneurs who have a small initial capital (from 3000 $) or are testing this line of business.

The program includes the production of two collections of decorative stone and three collections of paving stone materials, with the right to choose the number of square meters and the range of products offered.

with a daily rate of 50 sq. m.

| Item No. | Name | Quantity | Price | Amount |

| 1 | Concrete mixer | 1 | 570 | 570 |

| 2 | Scales 100 kg | 1 | 61 | 61 |

| 3 | Filling scales up to 10 kg | 1 | 28.50 | 28.50 |

| 4 | Vibrating table | 1 | 420 | 420 |

| 5 | Shovel | 4 | 2.68 | 10.72 |

| 6 | Plastic bucket 7 l. | 6 | 1.10 | 6.60 |

| 7 | Construction bucket | 4 | 2.04 | 8.16 |

| 8 | Cotton gloves | 10 | 0.21 | 2.10 |

| 9 | Measuring glass up to 1l | 2 | 0.72 | 1.44 |

| 10 | Electric drill with attachment | 1 | 29.57 | 29.57 |

| 11 | Water container 100l | 2 | 37.79 | 75.58 |

| 12 | Plastic bucket 10-15 l. | 4 | 1.05 | 4.20 |

| 13 | Extension cable 10-15 m. | 2 | 9.07 | 18.14 |

| 14 | Plastic glasses for pigment | 30 | 0.12 | 3.60 |

| 15 | PVC film 120 microns | 100 sq.m. | 0.09 | 9.00 |

| 16 | Particleboard (racks) | 72 sq.m. | 2.56 | 184.32 |

| Total: | 1432.93 | |||

| 17 | Forms | 50 sq.m. | 952.50 | |

| Technology package | 1000 | |||

| Total: | 3 385.43 | |||

| Name of shapes and photo of stone | Plastic thickness, mm | Price per 1 sq.m., $. | Quantity, sq. m. | Amount, $. |

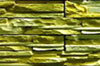

«SHALE №1» |

2.0 | 28 | 10.0 | 280.00 |

«VALAAM STONE»

| 2.0 | 30 | 10.0 | 300.00 |

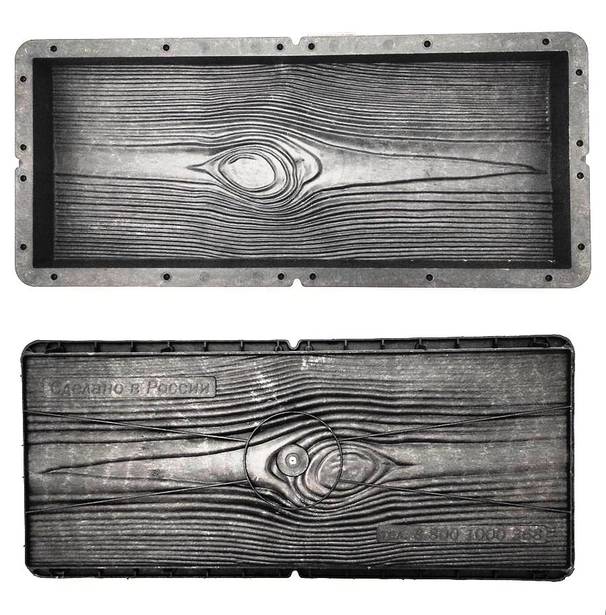

«SHIP BOARD»

| rigid form | 15 | 10.0 | 150.00 |

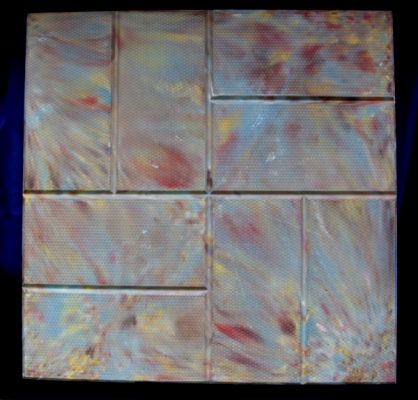

«8 BRICS»

| rigid form | 11.25 | 10.0 | 112.50.00 |

«CALIFORNIA» |

rigid form | 11 | 10.0 | 110.00 |

| Total: | 50.00 | 952.50.00 | ||

When a mini-factory operates in one shift, the monthly production norm is 1100 sq. m. products (for calculation we take 2 collections of decorative stone and 3 collections of paving slabs).

| № p/p |

Product name | Cost of raw materials, $./sq.m. * |

Monthly production rate, sq. m. | Cost of raw materials monthly production volume, $. |

Sales price, $./sq.m. ** |

Sales amount per month, RUR. |

| 1 | «SHALE №1» |

3.63 | 220.00 | 798.60.00 | 28.60 | 6 292.00.00 |

| 2 | «VALAAM STONE»  |

3,99 | 220.00 | 877,8.00 | 36.30 | 7986.00 |

| 3 | «SHIP BOARD» |

5.28 | 220.00 | 1 161.60 | 32.00 | 7040.00 |

| 9 | «8 BRICS» |

5.17 | 220.00 | 1 137.40 | 32.00 | 7040.00 |

| 10 | «CALIFORNIA» |

3.69 | 220.00 | 871.20 | 26.00 | 5720.00 |

| TOTAL: | 1 1.00 | 4846.60 | 34 078.00 |

| Item No. | Cost type | Value, $. |

| 1 | Raw materials (including delivery) | 4 849.60 |

| 2 | Rent of production facilities. and admin. area | 1000.00 |

| 3 | Electricity, including lighting (1760KW) | 157.70.00 |

| 4 | Cushioning of molds * | 70.05 |

| 5 | Equipment depreciation** | 29.99 |

| 6 | Staff salaries*** | 1500.00 |

| 7 | Administration salary | 600.00 |

| 8 | Advertising | 200.00 |

| 9 | Taxes**** | 2044.68 |

| Total: | 10 386,02 |

* - the calculation is made based on the fact that the molds can withstand 300 removals. Costs associated with delivery of forms are not included in the calculation. The latter depend on the delivery method (mail, road, railway, air transport or sea) and the tariffs of the transport company.

** - depreciation of equipment taking into account complete wear and tear over 3 years (1079,50:36).

*** - the salary of three workers at the production site.

**** - with a simplified taxation system, the tax is 6% of turnover.

The net income of the mini plant for the month (minus all costs) is:

34 078.00 - 10386.02.11 = 23 691.98 $.

Production payback is 1 month.

Costs for organizing production 3 385.43 $

Monthly profit minus production costs:

23 691.98 3 385,43 = 20 306,55 $.

The payback period for investments in a mini plant is 1 month.

Production profitability is:

(34078:10386,02)*100 = 328,11%

Notes:

- The approximate calculation of the feasibility study is based on our selected collections of stone in the presented color. (Stones have been selected that are most in demand in various areas of consumption - facade, plinth, columns, fireplaces, interior, fences, sidewalk).

- The customer has the right to independently choose collections of forms and their quantity (but not less than 5 square meters of each type).

- Calculation of payback is based on the condition of production and sale of 1100 sq. m. per month. With a smaller monthly volume of stone production and sales, the payback period increases.

- Production standards can be increased by switching to 2 or 3 shift work, which also leads to a reduction in payback periods and an increase in the profit of a mini plant.

- For each collection of stone, at least 37 types of coloring are possible - this allows you to diversify the range of products produced by mini factories.